The Injection Molding Machine is a device that is used in the manufacturing process to produce plastic products. It consists of two main parts: an injection unit and a clamping unit. A clamping unit is used to clamp the parts together. The clamping unit is a critical component because it helps the machine mold the parts into shape.

An injection moulding machine can make thousands or even millions of identical parts. It works with a variety of materials including thermoplastic polymers, glass, metals, and elastomers. The process also allows the manufacturer to mix and match materials to achieve specific properties and effects. Another benefit of an injection moulding machine is that the initial costs of production are extremely low and gradually decrease as you produce more parts.

Different types of Injection Molding Machines have a wide range of features and capabilities. Tonnage, platen size, and ejector stroke are some of the main differences between machines. A good molder will have a wide selection of machines for your specific requirements. To choose the right machine for your needs, choose a company that has experience with injection molding. You don't want to risk your project or your profits with a molder who doesn't have the right equipment or experience.

Cycle time is an important factor in injection molding. A well-designed tooling can help reduce cycle time and make the process run more quickly. You should also choose a company that has the latest injection molding machine technology. This technology is essential in making quality parts and minimizing assembly time. The more advanced your machine is, the more precise your parts will be. This also reduces the amount of labor needed during a production run.

Plastic pellets are a key component in the molding process. The pellets feed into the screw barrel of an injection molding machine and are compacted by heater bands. During this process, a large amount of heat is generated as the pellets 'rub' together. This sheer heat helps the plastic melt and turns into a molten state.

There are many types of injection molding machines. Each one has its own pros and cons. Consider your company's budget, product characteristics, and precision requirements when choosing the type of machine for your business. A machine that uses less electricity is a good choice if your company's energy budget is tight. A machine with high precision might be a better choice for you if your company is focused on quality and precision.

A machine's design dictates how the plastic is heated. Injection pressure is usually between 100 and 150 MPa and is applied for a certain period after the part is injected. Injection pressure is important because without it, the part may not pack completely. The machine size depends on your part size and cavitation, so it is essential to select the right one for your needs.

Injection molding is a very versatile process that can produce a range of parts in complex shapes. It is a faster way to produce parts. The injection mold can also create parts with complex shapes and a small wall thickness. Depending on the part's size and shape, injection molding can compete with complex machining and investment casting. If you are looking for a quick and easy solution to a pressing problem, an Injection Molding Machine could be just what you need.

Different industries require different types of Injection Molding Machines. The most common type of Injection Molding Machine is a hydraulic machine, which can perform repeated tasks with great precision. It also has an attractive price/performance ratio. Another type of Injection Molding Machine is the electric or hybrid machine. This type of machine has both electric and hydraulic power. These machines are ideal for a wide range of industries, and can produce parts of any size.

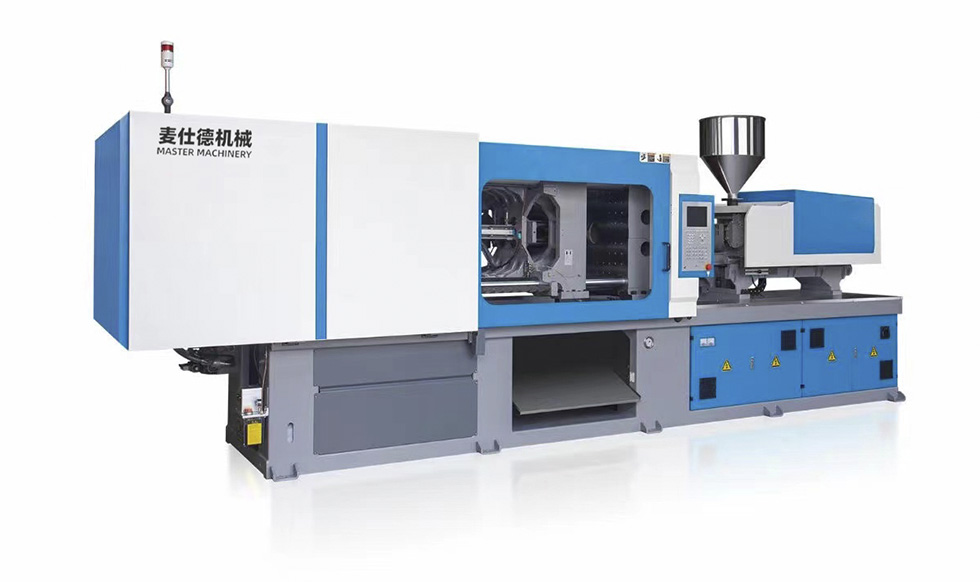

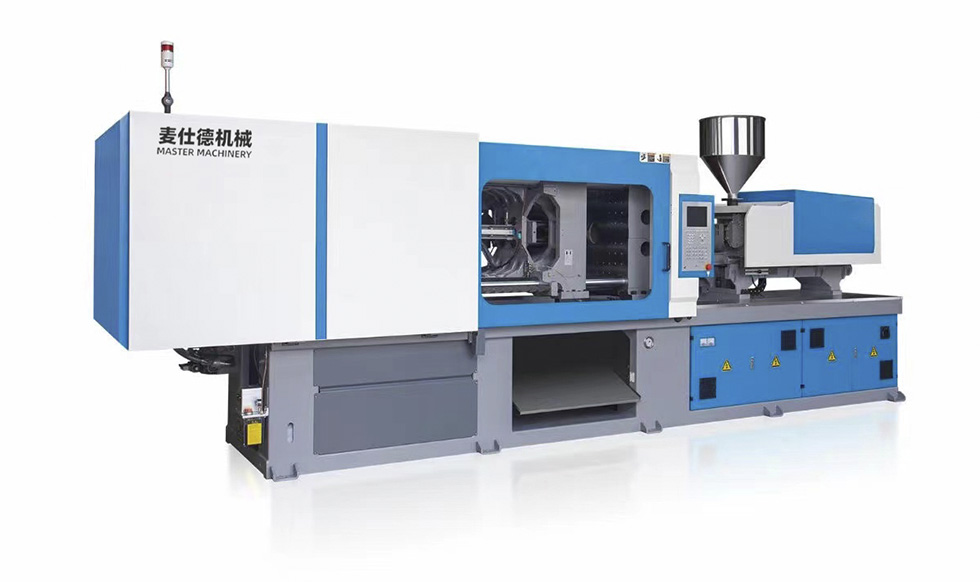

Horizontal Injection Molding Machine

Master Packing joint with Ningbo injection company to supply customers with 10T-4,000T, injection weight 45g---40,000g, more than 30 kinds of specification injection mold machine. Master injection machine has energy-saving, environment-friendly, low noise, high rigidity, excellent performance, fast response, and high efficiency. With advanced servo motor and famous brand parts, Master injection machine becomes many customers' optimal choice for Injection needs.

English

English España

España